The Era of Revolution - HY&Wei Tong Li

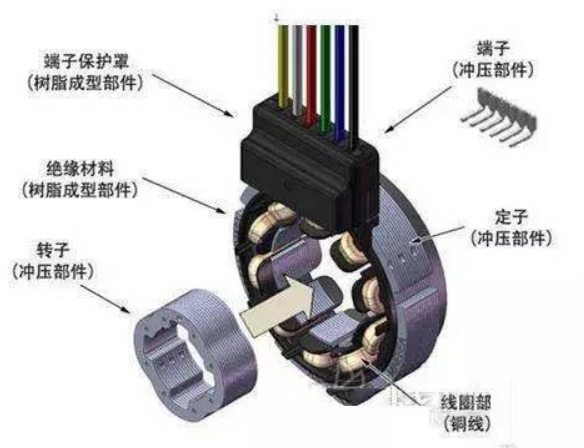

The motor rotor position sensor is often referred to as a rotary transformer or synchronous resolver, which is an electromagnetic sensor, abbreviated as a "rotary transformer". The rotary motor, which can be used to accurately detect the angular displacement and angular velocity of the motor rotor, is the most critical sensor in the motor controller. Composed of high-performance silicon steel laminations and enameled wires with special electromagnetic design, it has adaptability such as heat resistance, vibration resistance, impact resistance, and oil resistance. In recent years, due to the explosive growth of new energy vehicles, the motor core is getting increasingly publicity.

In August 2022, HY and Weitongli confirmed the first cooperation project for the iron core of the rotary transformer motor. After technical review by both parties, continuous improvement and optimization, the drawings were finally confirmed, our mold engineers have optimized the mold layout, reducing the steps of the mold and improving the utilization of raw materials, thereby achieving the goal of saving costs for customers. At the same time, to meet customer needs, the injection molding products of the rotary transformer core are also provided by HY, which is conducive to one-stop procurement for customers and improves the supply coordination of the product.

Our unremitting efforts have led to a smooth progress of this project. In just 30 days, the mold processing was completed. The stator and rotor samples were delivered in September 2022 in advance, and the first quality inspection was qualified. Formal mass production began in December 2022.

Stamping → pressurization → go/no go gauge → inspection → packing and bundling, high-speed stamping equipment+precise automated testing, ensuring product qualification rate and improving customer satisfaction.

The automatic oiling device of the equipment ensures the rust prevention of the iron core during the production process. We also store the products in stock in a constant temperature and humidity dust-free manner. The packaging materials for the products to be shipped meet the stable quality of the iron core during storage and transportation.

The success of the first cooperation quickly promoted the second cooperation between Weitongli and HY. In December 2022, another procurement contract for the stator and rotor was signed. This is the customer's recognition of the stamping of the stator and rotor core of HY, and it will also motivate our company to continue to stabilize quality and provide customers with more products that meet their expectations.

Faced with the fierce market for motor core stamping, HY staff stand in the perspective of customers, improve mold utilization, reduce product management costs, stabilize product quality, ensure product supply, complement each other with customers, strive for more market share for customers, enhance industry competitiveness, and work together.